Stainless steel containers for the highest demands

Tailor-made stainless steel solutions for pharmaceuticals, biotechnology and mechanical engineering.

Solutions for your processes

We guarantee process reliability through certified quality and complete documentation.

Sterilisation

Autoclavable and sterilizable container systems for pharmaceutical applications.

GMP-Konform

Design and manufacturing according to strict GMP guidelines and FDA regulations.

Temperature-controlled

Double-jacket systems for precise temperature control in critical processes.

Stirring technique

Integrated magnetic stirrers and mixing technology for homogeneous results.

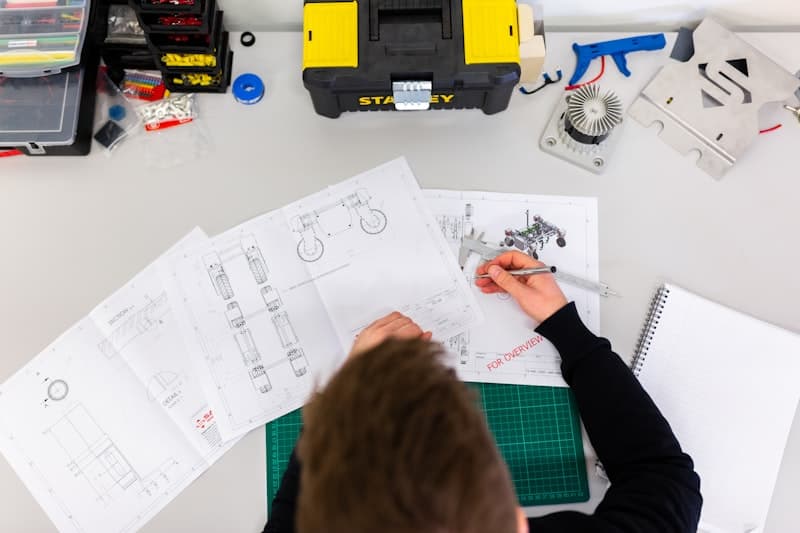

Precision in stainless steel

Our manufacturing combines traditional craftsmanship with state-of-the-art CNC technology. We guarantee surface finishes down to Ra < 0.3 µm and gap-free welds to meet the highest hygiene standards.

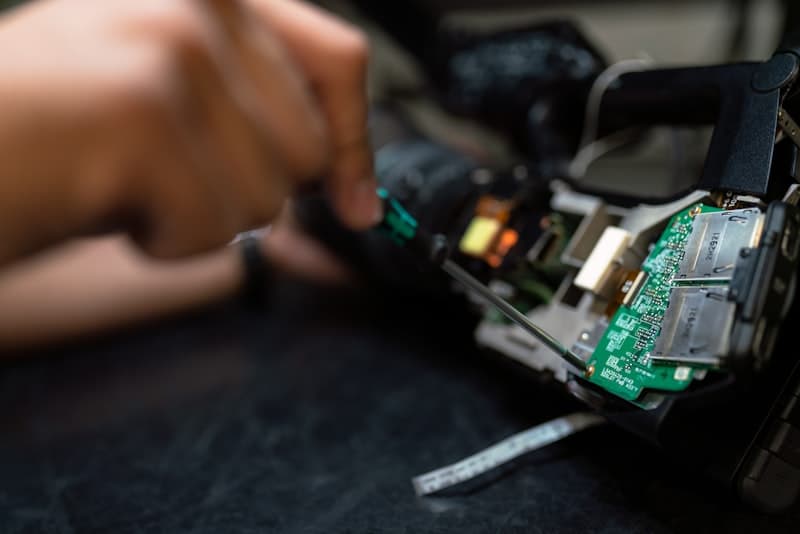

X-ray examination

Non-destructive material testing of the welds according to standard.

Batch traceability

Complete documentation of all materials used.

Vaccine production scale-up

We manufactured a series of 2,000 l mixing vessels with integrated magnetic stirring technology for a leading pharmaceutical company. The challenge lay in the extremely short delivery time while simultaneously meeting the strictest FDA requirements.

Detailed portfolio

Our expertise covers the entire field of stainless steel processing – from individual pieces to series production.

Container & Apparatus Construction

Pressure vessels, reactors and storage tanks with the highest surface quality.

Wireless Monitoring

Standalone monitoring systems for temperature, pressure and fill level.

Volume measuring body

Precision test dimensionals for calibration laboratories and calibration offices.

Documentation

Complete qualification (IQ/OQ) and material documentation.

Custom-made products

Custom designs tailored to specific customer requirements.

Services

Maintenance, retrofit and surface treatment.

Industries & Application Areas

Service beyond the purchase

Our work doesn't end with delivery. We support your systems throughout their entire lifecycle with certified services.

Comprehensive service – before and after the purchase

Do you have questions about feasibility, material selection, or design? Our engineers will be happy to assist you without obligation.

Request service